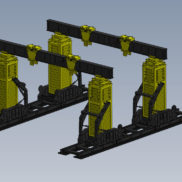

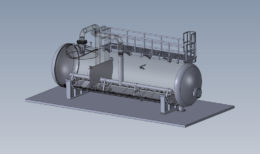

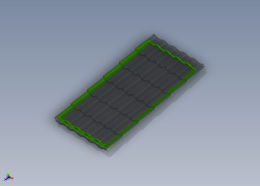

Together with Dennis Carty from Protorq3D, I designed and printed the MBL600 cantry from Enerpac.

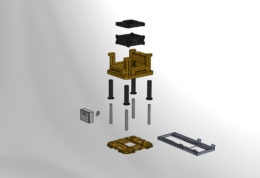

Enerpac wanted a scale model of the cantry to give potential buyers the option to view the construction up close and with exact details. The four columns contain 3 separate parts each, printed while being slid together to save volume and printing costs. These parts can be locked in position by a small wheel on each of the columns. The different parts are printed in nylon with the SLS process and coloured by spray painting. The whole model is subdivided so that is easy to build up and also repacked within minutes to a small volume for easy transportation.

We are also glad with the final outcome of this project. We think that, more and more companies will benefit with simular prototyping projects in the coming future. Looking forward to share another project with you!